Resistograph Drilling Effective in Assessment of Charred Timbers in Historic Structures

Recently I had the opportunity to work with a client assessing the condition of fire damaged timbers in three historic structures located in Louisville, Kentucky. The fire occurred in July of 2015 and happened during the initial rehabilitation of the three buildings. The fire broke out in the middle building and managed to spread into each adjacent building and burned for more than 24 hours. While several timbers and floor joists were completely consumed, many others were damaged and remained after the fire was put out. Even though several of the elements were damaged from the 2nd, 3rd and 4th levels of the structures, it was of utmost importance to the client, and the local Historical Society, that as many of the charred elements be salvaged and reused as possible.

I've always been impressed by the ability of wood to insulate itself during a fire as shown in the figures below. The fire performance characteristics of wood are well documented, and involve several factors. In general and simple terms, the timbers can be exposed to various levels of flame, resulting in a wide range of elevated temperatures, for prolonged periods of time. As wood burns it develops a char zone that acts as an insulating layer. The temperatures in the remainder of the cross section beyond the char zone drop significantly due to the insulation effect of the char layer and several other wood properties. In the 1/4" to 5/8" region beyond the char layer permanent strength loss can occur, depending on the property being evaluated, and therefore, must be accounted for in some structural calculations. Depending on the severity of the fire and the damage to the timbers, there may be an opportunity to salvage the materials and reuse them. In this case I was amazed to find myself standing inside three historic buildings that had been subjected to a serious fire, yet there was an opportunity to salvage several of the timbers.

Figures 3 and 4 from Post-Fire Analysis of Solid-Sawn Heavy Timber Beams. White, Robert H. and Frank E. Woeste. Structure Magazine, November 2013.

My scope of work for this project was to develop a simple visual criteria for the client to use for the assessment of all the burned elements that were removed from the three structures. I realized that this project was a good opportunity to use a Resistograph to determine char layers and effective cross sections. So, the first step was the development of the visual criteria for the various char levels that were observed in the burned timbers. Then, using the Resistograph, I drilled several timbers representing each char level to determine the mean char depth. From that information I was then able to determine the effective cross sections for each char level. Finally, I recommended residual allowable properties that could be applied to the effective cross sections. Using all this information the client was then able to then perform all the necessary structural calculations and then inspect all the charred timbers removed from the building and determine which were salvageable and which were not.

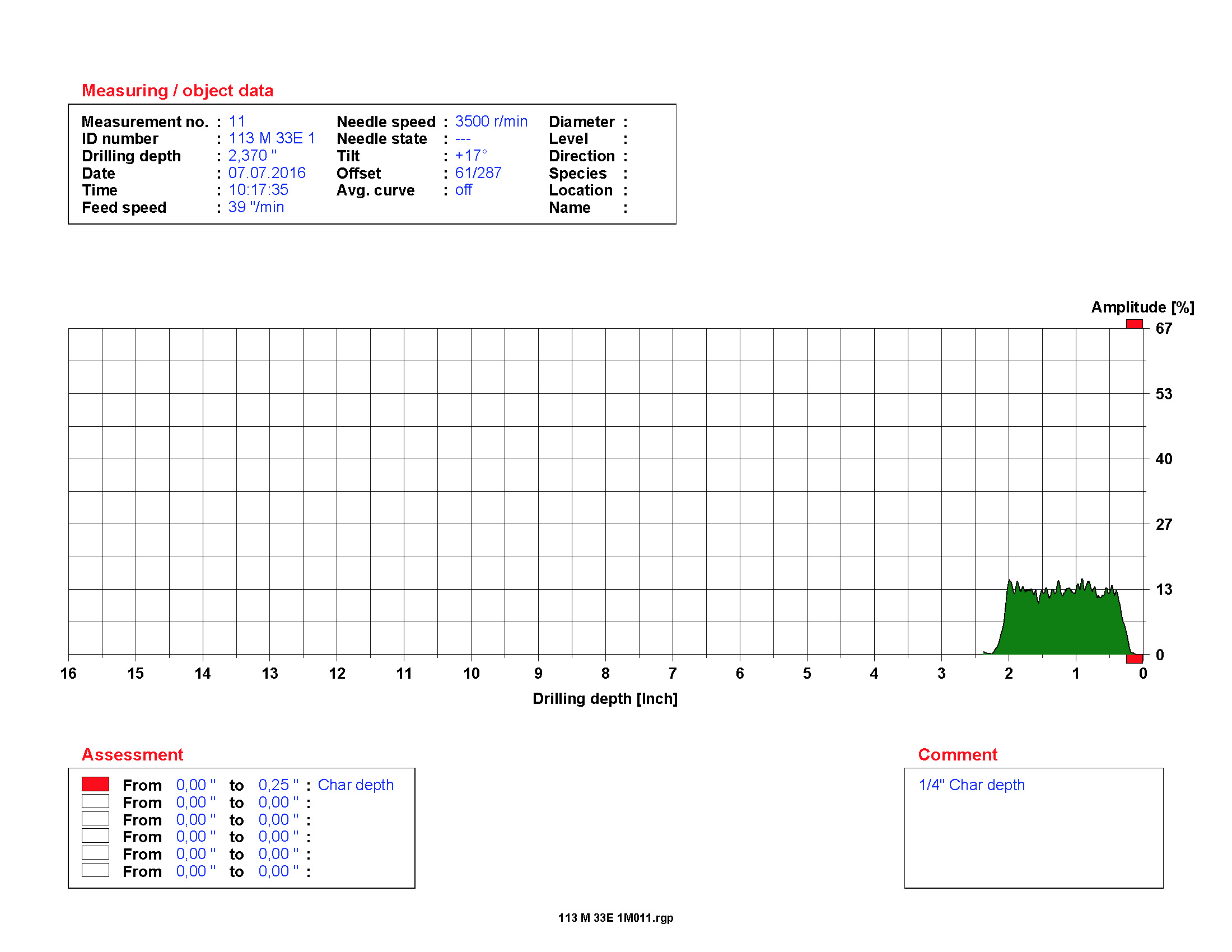

The visual rating system I developed was as follows with example Resistograph charts,

Level 1 – Represents only a darkened surface discoloration of a member. Full cross section is still visible (Photos 1 and 2).

Level 2 – Represents the initial development of cubical charring. Full cross section of elements is still visible (Photos 3 and 4).

Level 3 – Represents full development of cubical charring. Cross section of element is still visible, however, corners of elements have become rounded (Photos 5 and 6).

Level 4 – Represents full development of cubical charring and cross section is visibly compromised (Photos 7 and 8).

Photo 1 - Level 1 charring, slight or no cubical formation visible (courtesy of GEM Engineering).

Photo 2 - Char depth pf 1/8" detected in a level 1 rated timber.

Photo 3 - Level 2 charring, minor cubical formation visible (courtesy of GEM Engineering).

Photo 4 - Char depth of 1/4" detected in a level 2 rated timber.

Photo 5 - Level 3 charring, cubical formation with some visible loss in cross section.

Photo 6 - Char depth of 9/16" detected in a level 3 rated timber.

Photo 7 - Level 4 charring, distinct cubical formation, and visible loss in cross section.

Photo 8 - Char depth of 3/4" detected in a level 4 rated timber.

For a Level 1, the mean char depth was found to be 0.15” and for a Level 2 the mean char depth was found to be 0.25”. For Levels 3 and 4 the mean char depths were found to be 0.4” and 0.70”, respectively. Using this data and the Resistograph results, effective cross sections were determined. Next, the residual allowable design values of the various elements were determined. Those values were based on the species of the timbers and the published allowable design values in the Supplement to the National Design Specification. I also used the recommendations for adjusting allowable design values provided in Evaluation, Maintenance and Upgrading of Wood Structures, A Guide and Commentary, American Society of Civil Engineers (ASCE, 1982), Post-Fire Analysis of Solid-Sawn Heavy Timber Beams by Robert White and Frank Woeste (Structure Magazine, November, 2013), and Wood and Timber Condition Assessment Manual by Robert Ross, et al (Forest Products Society, 2004).

In the end I was able to provide my client with the ability to inspect all the charred framing elements removed from the buildings. Those found to be acceptable were selected so that they could be cleaned and then reused inside the buildings. Based on the results of the evaluation, I found that the methods used on this project were effective for the testing of charred wood elements and ultimately the determination of effective cross sections and residual allowable design values.